The School was bustling with the 9th and 10th graders on June 23, 2018. We were being taken on our first field trip of the year. We assembled in the ground floor pit. AO Mrs. Christina Ma’am and the Campus Head Mrs.Nancy Mam greeted us and we said a small prayer. We were all very excited when the buses left the campus at 9 O’clock.

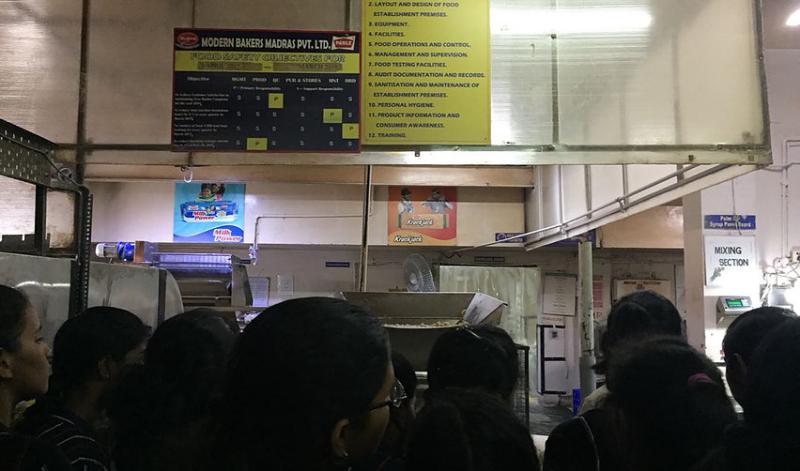

We started our journey towards the factory. Most of the travel was through the highways and toll gates. We reached the plant at 9.35 am. The sweet smell of biscuits came breezing into our nostrils, the moment we crossed the tall gates bearing the factory name “Modern Bakery”. We divided into pairs and peered about curiously at the many boards and notices, laying out rules and advertisements.

The puffing and whirring of the machines inside the buildings could be heard. The way towards the office entrance was occupied on the sides by a parking slot, a cylinder bank and a small garden. After climbing a small fleet of stairs, we filled a small hall which had doors to labs, offices, document rooms and a small auditorium. We were shown a presentation in the auditorium about how all the products are made in the factory using an animated video clip.

Then we made our way down to the factory buildings after receiving a packet of biscuits and toffees. The sweet biscuit smell returned to us the moment we set foot inside the production unit. We strolled through the neatly arranged stacks of boxes of biscuits, many unknown machines whirring and chunking, and reached the end of the corridor, where we the employees explained the making on biscuit dough.

The dough was mixed by a huge machine in the shape of a cart and we were given a sample of the dough to see, not to taste, but many of us popped it into our mouth without realizing it is not yet cooked

We saw it the other way, the packing first, then the baking. Long, horizontal stacks of round biscuits made their way to the packing area robotically on an open tube, then parted itself into seven and the packing machine put them into transparent plastic sheets and into its red plastic wrap. The workers took 6-7 packets and covered it with a plastic cover and arranged them in the boxes we saw at the entrance. The employees told us that if a packet is not sealed or packed properly, it would be recycled by grinding the biscuit into powder and adding them to the dough.

Photo Courtesy : https://www.theschramacademy.org/

Then we moved to the baking area. The rows of biscuits, freshly baked, could be seen moving on the conveyor belt into the packing area. Few students took some biscuits from the conveyor belt and tasted it. It was not like the packed and stored for months biscuits that we usually eat. This was really hot and tasty, and was brittle and fresh. After watching the machine smartly pile up the biscuits for some time, we left the factory and headed for the buses waiting for us, to be taken back to the school.

It was a very YUMMY and TASTY trip!!

What’s up, of course this paragraph is actually fastidious and I have learned lot of

things from it on the topic of blogging. thanks.